Reliable sensor solutions for industrial automation

Accurate measurement data is indispensable for more efficient, safe and reliable industrial processes. Althen Sensors & Controls provides smart sensor solutions that measure and control important variables, from weight and position to vibration and movement. They ensure accurate and precise process automation, for example when filling juices, dosing pharmaceutical ingredients or adding substances in chemical production.

We provide customized solutions for the: beverage and food industry, pharmaceutical industry, chemical industry, among others. Our sensors help you make your machines work smarter, faster and largely autonomously.

- In packaging and transport processes, our advanced weighing systems increase efficiency in fill level determination, check weighing and dosing.

- Also suitable for hoisting and lifting systems.

- Our weighing modules also ensure safe and stable operation of vertical transport systems such as cranes and elevators

We have a wide and robust product range. Our portfolio includes

- Load cells for precise weighing applications

- Amplifiers for measuring equipment

- Linear position sensors for precise process control

- Vibration sensors and data loggers for permanent monitoring and analysis

Applications of industrial automation

Control routing in pulse systems

In automated filling systems, load cells and weigh cells with appropriate amplifiers ensure that the weight of bottles, cans or bags is accurately controlled. Control weighing at the end of the line ensures that only correctly filled products are processed or packaged.

Level measurement in mixing tanks

In the production of chemicals or medicines, the precise measurement of the filling level using pressure sensors in reactors or tanks is of great importance. Load cells under the container enable continuous, non-contact and hygienic level measurement. This is ideal for aggressive or sensitive media.

Dosing control in tablet presses

In tablet production, linear position sensors and load cells are used to ensure that each tablet is pressed with exactly the right amount of active ingredient. The sensor system controls the dosing slides and monitors the pressing force in real time.

Vibration monitoring on mixers

Vibration sensors are installed on rotating equipment such as agitators, mixers or pumps to detect machine malfunctions at an early stage. These detect imbalance, bearing defects or other irregularities; data loggers continuously record the changes.

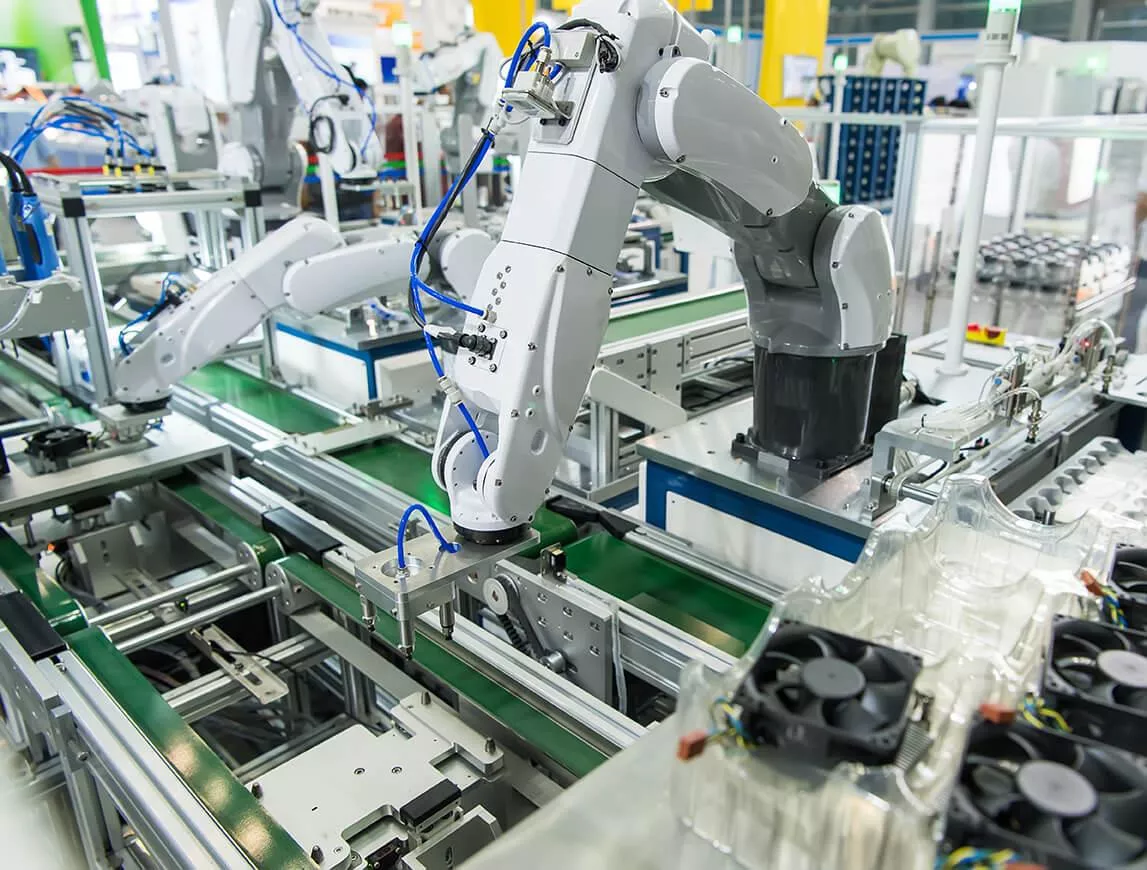

Position detection on packaging lines

In high-speed packaging systems, laser position sensors or linear position sensors monitor the movements of gripper arms, lift tables or cutting units. This ensures that each work step is precisely timed and repeatedly accurate.

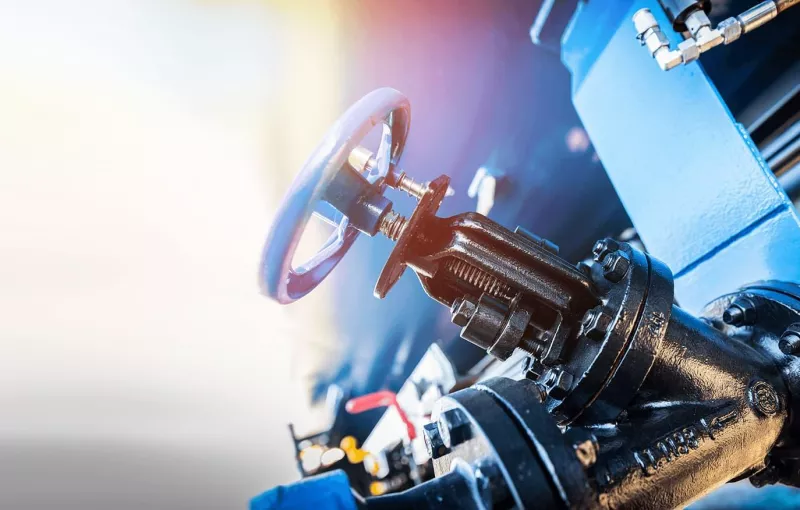

Press force monitoring in forming systems

In hydraulic or mechanical presses, the applied force is continuously monitored during the deformation process. Pancake load cells record the press force with high accuracy. This prevents material errors, improves process quality and allows complete documentation for quality assurance.

-

Superior sensor technologyIn product an process

-

Long-term PartnershipIn process and automation

-

Reliable and ExperiencedProven trackrecord over 75 years

-

Innovative and NewState-of-the-art products and developments

Product categories

Single point load cells

- For smaller and medium-sized weighing platforms

- Excellent off-centre load compensation

Intrinsically safe load cells

- Measuring range 0.25 kg to 750 ton

- Approved for use in combustibel areas

- Various measuring directions available

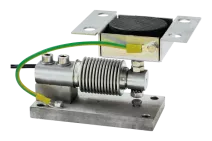

Weighing modules & mounting kits for load cells

- Measuring range 5 kg to 100 ton

- Specially designed for loadcells

- Best weighing performance

Measuring amplifiers with bus interfaces (OIML)

- Connect up to 32 instruments

- Amplifiers/indicators for load cells

Indicators with bus interfaces (OIML)

- Indicators for load cells

- Various protection rates available

Digital indicators for weighing systems

- Indicators for weighing systems

- <0.01 % FS Linearity

Our clients

Our projects

Discover our projects & applications for automationRelated products

GL260 Compact Data Logger

- Measuring ranges: voltage, temperature, humidity

- Measuring channels: up to 10

- G-REMOTE / New service with cloud server

ALF318 Pancake Force Sensor

- Measuring range: ~1 kN to ~500kN

- With high axial & lateral mechanical stiffness

- Various designs possible on request

PCC420A Series 4-20 mA Vibration Sensors

- Continuous trend display of machine vibration

- True RMS or calculated peak output

- Easily integrated into existing process control systems

MonoDAQ-U-X

- Power and signal isolation between USB and front end

- Max. sample rate: 50 kS/s, resolution: 16 bit

- Can connect up to 2 full bridge strain gauges or up to 4 thermocouples

P103 Short stroke linear inductive position sensor

- Compact stainless steel housing for space-constrained environments

- Travel range from 2 mm to 50 mm

- Multiple electrical and mechanical configurations

18FLPA Series Linear Potentiometer

- Measurement range 15 mm and 100 mm

- Resistance value: 500 Ω to 20 kΩ

- Robust conductive plastic model

Process monitoring: perfect interaction between hardware and software

The software and hardware components of a system must fit together perfectly. The program ensures that you always have an overview of the machines. You can also monitor your systems remotely via the Web Server Master. In this way, you can control and monitor your weighing system in a targeted way and see immediately when a station fails or causes problems.

Our weighing solutions are particularly compatible. The automation systems support the digital interfaces of most PLC manufacturers. They can be easily connected via one of the many bus systems available on the market.

Automation solutions for your requirements

Althen offers you flexible automation solutions for your measuring tasks. Among the various designs, even for very small or large nominal loads, you are guaranteed to find the right product for your requirements.

Some force transducers are also suitable for use in explosive environments. The robust housing prevents dust or water vapor from entering, ensuring reliable and accurate measurements - even under challenging conditions.