We live in a world of sensors

Sensors are essential in today’s increasingly industrial and automated world. Our sensors and measurement systems are vital to the next generation of data-driven technology. We offer different types of sensors which are based on various measurement technologies to fullfill applications across a wide range of industries. Althen is your allround partner for standard and custom designed sensor solutions. We provide solutions with sensors and measurement systems for Test & Measurement, OEM and Industrial IoT Applications.

What is a sensor?

A sensor measures a physical quantity. The variables are located in the following areas: pressure, force, inclination, displacement, acceleration, temperature, strain, vibration or any one of a great number of other environmental phenomena. Sensors convert the measured quantity into a standardized control signal that is converted to a human-readable display at the sensor location or transmitted electronically over a network for reading or further processing.

Application areas

The most common areas of use for sensors are diverse and cover numerous industries and applications. The most common include

Technology

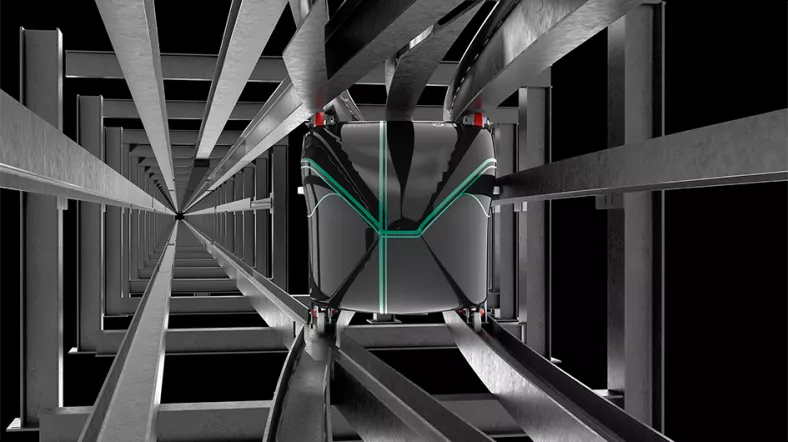

There are a variety of different sensor technologies based on different physical, chemical or biological principles. Each sensor technology has specific strengths and is selected depending on the application and environment. When used in combination, they enable advanced systems such as autonomous vehicles, smart devices or industrial monitoring systems.

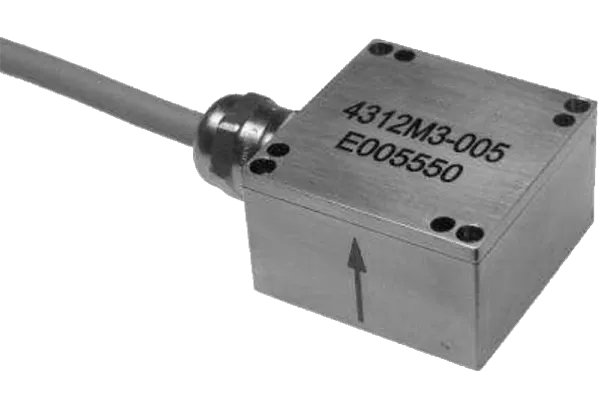

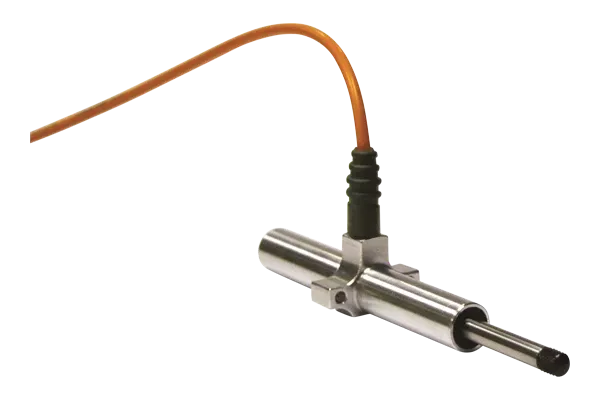

Mechanical sensors

Examples: Pressure, force and acceleration sensors.

How they work: Convert mechanical deformations or movements into electrical signals.

Technologies:

- Piezoelectric: Utilises electrical charges generated by mechanical pressure in piezoelectric materials.

- Strain gauges (DMS): Change in resistance due to material deformation.

- Capacitive: Change in the electrical field due to a change in distance or position.

Optical sensors

Examples: Light sensors, colour sensors and optical distance sensors.

How they work: Detect light intensity, wavelength or reflection.

Technologies:

- Photodiodes and phototransistors: Convert light directly into electrical signals.

- LIDAR (Light Detection and Ranging): Measures distances by reflecting laser beams.

- Spectroscopy: Breaks down light into wavelengths for chemical analysis.

Thermic sensors

Examples: Temperature sensors, thermal radiation sensors.

How they work: Detect temperature by thermal conduction, radiation or thermal expansion.

Technologies:

- Thermocouples: Voltage change due to temperature differences.

- Resistance thermometers (RTD): Change in resistance due to temperature.

- Infrared sensors: Detect heat radiation without direct contact.

Electrical sensors

Examples: Voltage sensors, current sensors.

How they work: Detect electrical variables such as voltage, current or resistance.

Technologies:

- Hall effect sensors: Utilise magnetic fields to measure electrical currents.

- Shunt resistors: Measure current indirectly through voltage drop.

Magnetic sensors

Examples: Compass sensors, magnetic field sensors.

How they work: Detect changes in magnetic fields.

Technologies:

- Hall effect sensors: Voltage is generated by a magnetic field.

- Fluxgate sensors: Measure changes in the earth's magnetic field.

- GMR (Giant Magnetoresistance): Utilises resistance changes in magnetic fields.

Capacitive and inductive sensors

Capacitive sensors: Measure changes in capacitance, e.g. for touchscreens or proximity detection.

Inductive sensors: Detect movements or positions through changes in magnetic fields, e.g. in metallic objects.

Your advantages

Our sensors combine state-of-the-art technology with targeted customisation to offer maximum efficiency, reliability and flexibility. They thus form the basis for high-tech solutions in numerous industries and help companies to develop future-proof products. At Althen we offer you:

- High-quality sensor solutions

- Flexibility

- Development of customised solutions

- Fast prototyping

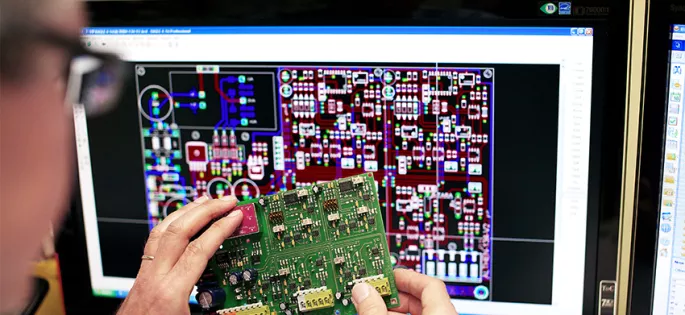

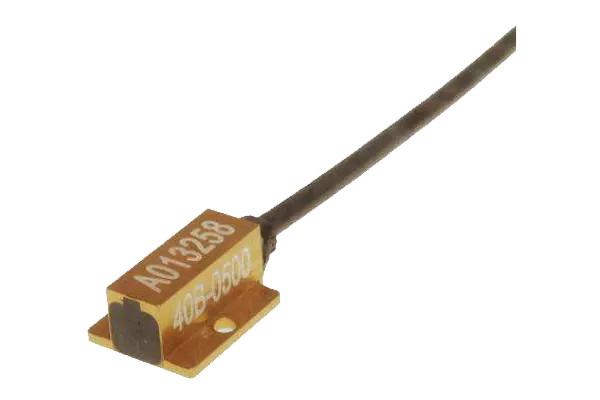

Customised sensor solutions

Our in-house production facilities enable us to develop customised solutions for any measurement challenge. Althen has more than 40 years of experience with many different types of sensors and measurement technologies. This enables us to find the best solution for your application! Let us know your metrological challenge - we will advise you on standard sensors and/or develop an individual, customised solution for you.

Sensor categories

Quality management certification

Althen Sensors & Controls is certified to ISO 9001. It is the most widely used and most important standard in quality management. ISO 9001 focuses on the optimisation of processes in order to improve performance within the company and meet customer requirements in the best possible way. This certification confirms that we reliably fulfil the high quality requirements of our stakeholders and ensure the continuous improvement of our business processes.

Our sensors in projects

Discover our projects and applications

Loadcell technology helps to accurately weigh a bridge

Liquid level transmitters for OEM oil tanks

Searching for the right sensor?

Do you need support, advice or an offer for your project? We are here to help you.