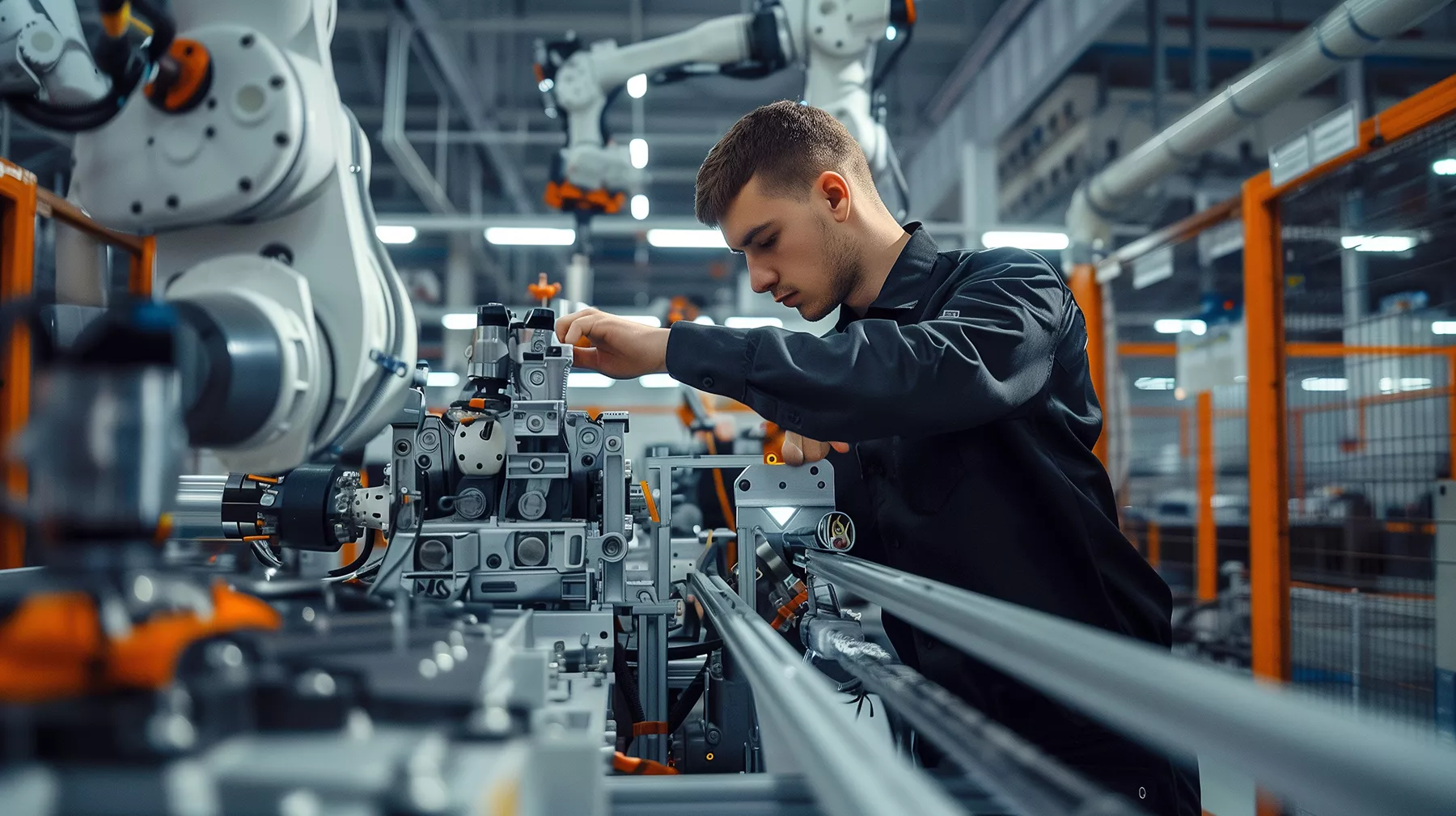

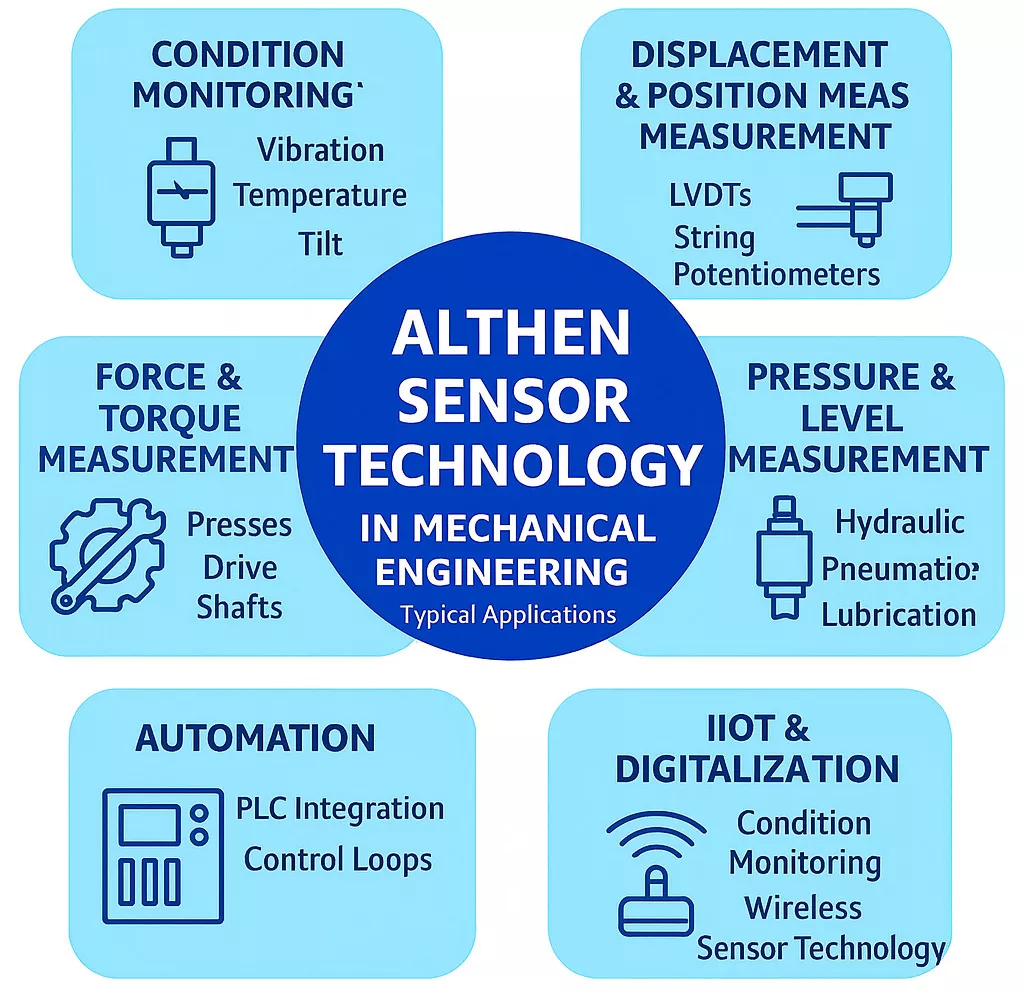

Sensor and measurement solutions for mechanical engineering

Precision, reliability, and efficiency are crucial in mechanical engineering. Whether in development, quality assurance, or series production, accurate measurement data is the basis for reliable processes and innovative products. Althen offers sensors, measurement systems, and complete solutions that are specially developed or adapted for mechanical engineering.

Whether in the chemical industry, food, plastics, metal, wood, paper, or textile processing, our systems measure force, pressure, torque, temperature, displacement, vibrations, and more—for optimal control, monitoring, and documentation of your processes.

Customized applications in mechanical engineering

Tensile force measurement in paper machines

In paper processing, precise control of web tension is crucial for the quality of the end product. Cylindrical force transducers are used here to measure the tensile force directly in the roller bearings (ALF214 cylindrical force transducer). Real-time monitoring of the tensile stress ensures uniform material guidance, preventing tears and production errors. Their robust design enables reliable operation even under high loads and in harsh industrial environments.

Clamping force monitoring in filling machines

Precise force control also plays a key role in filling and packaging machines. Donut ring force sensors are used here to monitor clamping forces (ALF207 Load washer). They measure the forces used to secure containers in order to prevent damage and ensure safe positioning during the filling process. Thanks to their compact design, these sensors can be easily integrated into existing systems, which increases process reliability and reduces downtime.

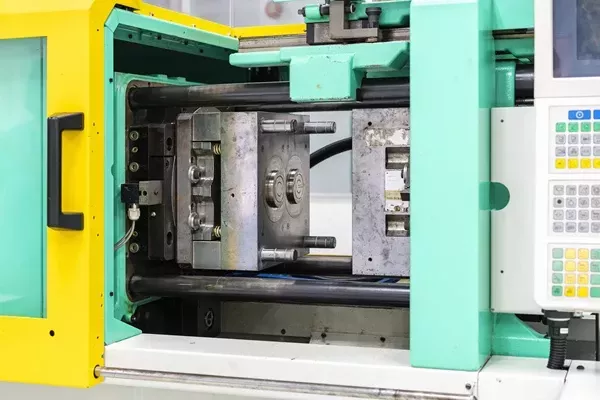

Position control in injection molding machines

In injection molding machines, the correct positioning of the tools is a decisive factor for the dimensional accuracy and repeatability of the process. Linear position sensors are used here, among other things, to precisely monitor the movements of the tool slide and the injection units. These sensors provide high-resolution position data that is necessary for precise control of the machine, thereby contributing to process optimization, improved product quality, and reduced scrap.

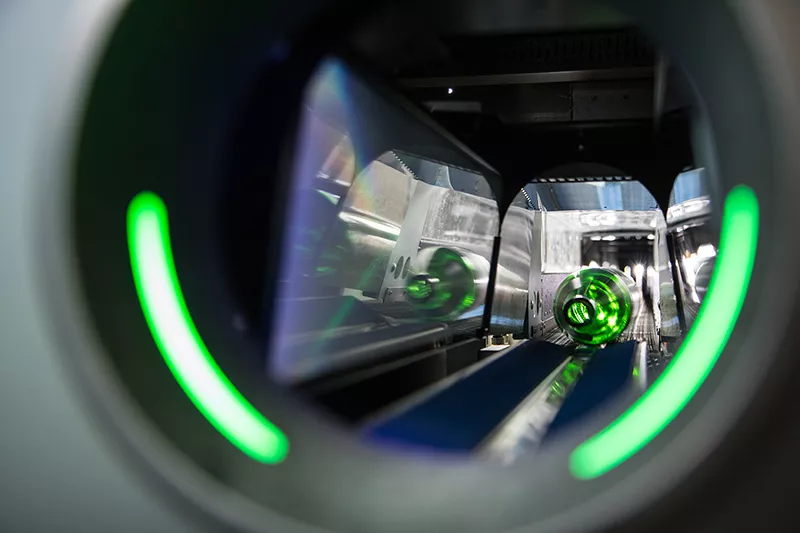

Pressure measurement in reverse vending machines

Pressure sensors are used in sorting machines and reverse vending machines to monitor air or hydraulic pressure in drive and separation units (AP-0010-G-Z547 pressure sensor). They ensure reliable detection of bottle movements and safe operation of pneumatic gripping or separation mechanisms. Thanks to their high measuring accuracy and compact designs, these sensors deliver precise real-time data even in confined installation conditions, ensuring process reliability and reducing malfunctions during operation.

Cylinder pressure measurement in mixing machines

ATEX pressure sensors are used in mixing and kneading machines to monitor the hydraulic pressure in the cylinders. They precisely measure the pressure conditions required for pressing and moving the mixing tools (AGS4200 standard pressure transducer). Thanks to their explosion-proof design, these pressure sensors are ideal for use in potentially explosive areas, such as those encountered when processing chemical or dusty materials, thus ensuring a safe and controlled mixing process.

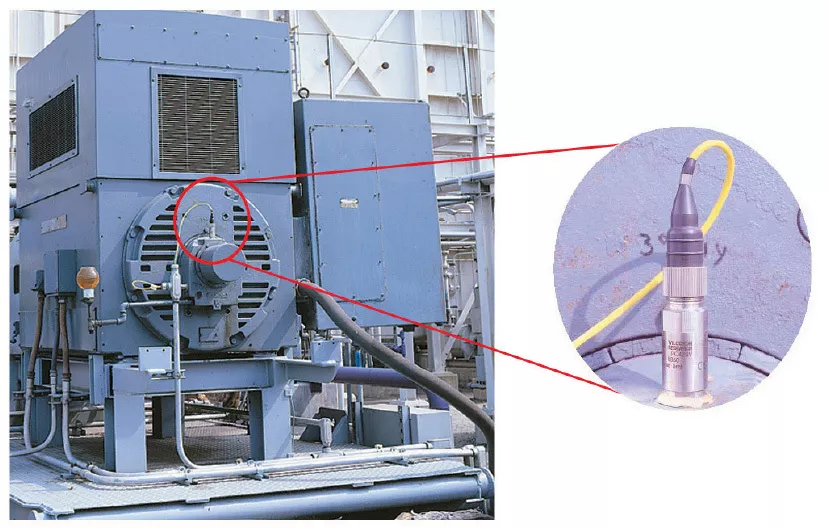

Bearing monitoring with vibration sensors

Vibration sensors are used in close proximity to the bearing location to monitor the condition of roller and plain bearings. They detect vibrations and enable early detection of typical damage such as imbalances, misalignments, or wear (PCC420A series – vibration sensors). The data is used for limit value monitoring or analysis in the frequency range and can be integrated into existing maintenance systems. This supports condition-based or predictive maintenance – for higher availability and lower maintenance costs.

Product categories

Cylindrical force sensors

- Measuring range 30 N to 5 MN

- With quantified extraneous load

- Accuracy from 0.5% to 0.05%

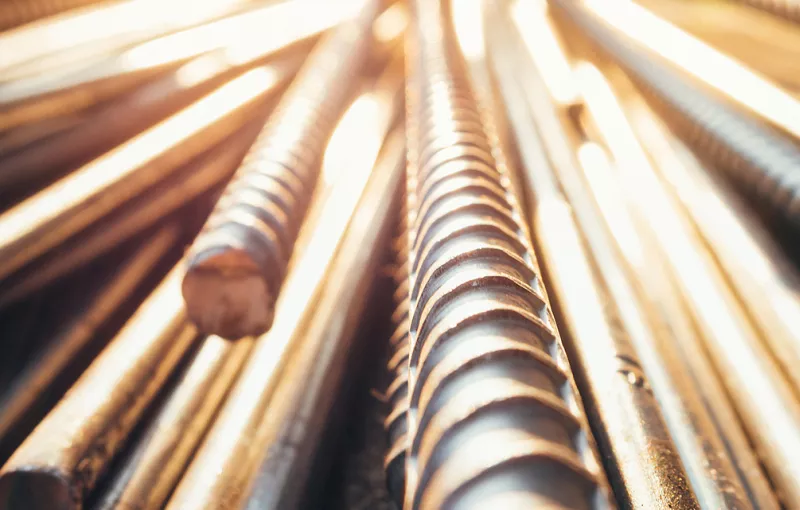

Donut ring force sensors

- Measuring range 7,5 kN to 4 MN

- Ideal for testing cables, rods and bolts

- Low hysteresis and non-linearity

General purpose pressure sensors

- Measuring range -1 to 10.000 bar

- Standard Low-cost

- Variety of options available

Intrinsically safe pressure sensors

- Measuring range 0 to 1.600 bar

- ATEX approved for hazardous areas

- Durable, stable, reliable & accurate

Incremental linear encoders

- Measuring range 50 mm to 2.000 mm

- Position feedback in electrical signals

- Up to 2,5 µm resolution

Rotary encoders

- Resolution from 5 bit to 2/36.000 pulse/revolution

- Convert angular position to analogue / digital data

General purpose vibration sensors

- Measuring range 5 g to 1.000 g

- Noise from 1.4 mg to 0.1 µg

- Excellent for industrial monitoring

Magnetostrictive linear position sensors

- Measuring range 100 mm to 2.000 mm

- Temperature, shock & vibration resistant

- Wear- and maintenance-free

MEMS inclinometers

- Measuring range from ±1° to ±90°

- Accuracy/Resolution up to 0.001°

- One & two-axis versions available

Intelligent condition monitoring of machines

- Wireless measuring nodes for measuring triaxial vibrations and surface temperatures

- For rotating devices such as pumps, motors and compressors

- Gateway for communication to transfer data to the cloud

-

Superior sensor technologyIn product an process

-

Long-term PartnershipIn process and automation

-

Reliable and ExperiencedProven trackrecord over 75 years

-

Innovative and NewState-of-the-art products and developments

Why is Althen your perfect partner for sensor and measurement technology in mechanical engineering?

- Many years of expertise & manufacturer-neutral advice

- Althen has over 45 years of experience and offers sound, manufacturer-neutral advice. This guarantees that you get exactly the sensor solution your application needs – without being tied to a specific manufacturer.

- Customized and standardized solutions

Whether you need a standard sensor or a fully customized solution, Althen develops and manufactures OEM sensors, test & measurement modules, and IIoT sensor technology. Your requirements are incorporated directly into the manufacturing process – with high precision and reliability in accordance with ISO 9001. - Turnkey measurement systems for industrial applications

With plug-and-play systems such as vibration, inclination, or weighing systems (e.g., VibroLine, Vibromatix, mobile weighing solutions), Althen delivers complete turnkey solutions – precisely tailored to complex machine scenarios. - Robust sensor technology for tough applications

Althen sensors – such as vibration transducers – are manufactured in stainless steel housings, often with IP 67 protection and integrated charge amplifiers. They are suitable for high vibrations, extreme frequencies, or even submersible operation – ideal for demanding machine environments. - IIoT expertise & condition monitoring

Althen is the partner of choice for wireless condition monitoring in modern machines: battery-powered sensor nodes, mesh networks, robust gateways, and dashboards make it easy to retrofit your systems – without any major infrastructure changes. - Comprehensive service & support

Althen not only supplies sensors and systems, but also supports you with consulting, prototyping, calibration, training, and rental services. Everything from a single source—reliable, transparent, and cost-conscious.

Our customers

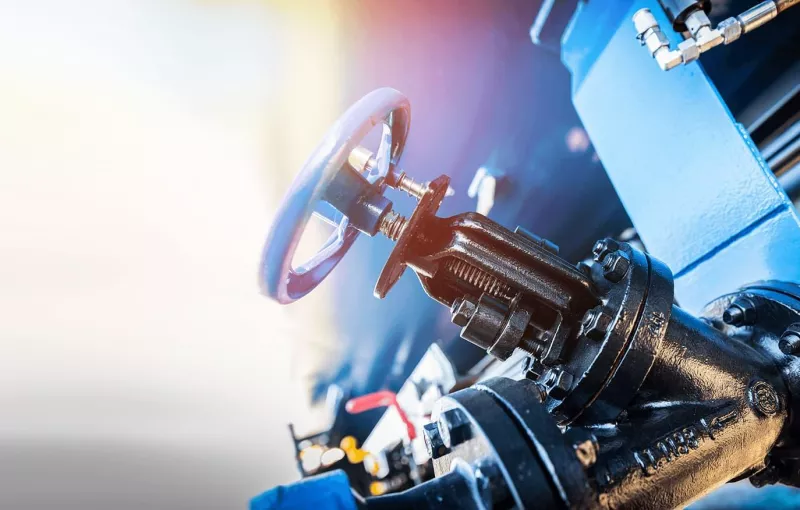

Insight: Inductive ATEX position sensors in offshore and chemical plants

Offshore platforms and chemical plants are subject to extreme conditions: potentially explosive atmospheres, high humidity, aggressive media, and extreme temperature fluctuations. Intrinsically safe inductive linear position sensors are used here to monitor linear movements and positions precisely and safely, without the risk of ignition sources.

Typical Applications:

- Position monitoring of valves, slides, and pistons in hydraulic or pneumatic systems

- Stroke control in control valves

- Travel measurement in pump and conveyor systems

Advantages of inductive displacement transducers:

- Non-contact measurement, wear-free and low maintenance

- Robust design, resistant to chemicals, dust, and moisture

- High measurement accuracy even in harsh environments

Intrinsic safety for operation in hazardous areas

ATEX certification is crucial here, as it ensures that the devices are approved for use in potentially explosive atmospheres. This prevents ignition sources from occurring even in the event of malfunctions - an essential factor for operational safety in oil, gas, and chemical applications. In addition, these sensors are also used in drilling rigs, the process industry, and in safety-critical areas of energy and raw material extraction.

Insight: Vibration monitoring in mechanical engineering

Vibration monitoring is a key element in modern mechanical engineering for the early detection and prevention of unplanned downtime, bearing damage, and efficiency losses. Whether in plant monitoring of entire production lines or in condition monitoring of individual components such as pumps, drives, or turbines, vibration sensors provide reliable data for condition monitoring and predictive maintenance.

Typical areas of application in mechanical engineering

- Plant monitoring: Detection of imbalances or resonances in complex machine structures.

- Pump monitoring: Early detection of cavitation, misalignment, or bearing damage.

- Bearing monitoring: Measurement of high-frequency pulses to identify rolling bearing or plain bearing wear.

- Drive monitoring: Detection of gear damage or imbalances in motors and gearboxes.

- Fan and compressor monitoring: Vibration analysis to reduce energy losses.

- Turbine monitoring: Real-time data to prevent structural overload.

- Conveyor system monitoring: Ensuring a continuous flow of material in bulk goods or piece goods logistics.

- Laser and precision systems: Active vibration suppression to maximize machining accuracy.

Sensor solutions from Althen for vibration monitoring

Different sensor types are available depending on the measurement task:

For general plant monitoring:

- PCC420-A Series – robust, with 4–20 mA output for easy integration.

- 786A – General purpose vibration sensor – Standard vibration sensor for industrial environments.

- 993B-7 Multi-axis vibration sensor – 3-axis measurement for comprehensive analysis in complex systems.

For high-frequency monitoring (e.g., bearing analysis):

- 997 High-frequency vibration sensor – ideal for bearing damage or impulse analysis.

- 793-10 General purpose vibration sensor – robust sensor for critical high-frequency applications.

For low-frequency vibrations & precise machines (e.g., laser systems):

- 731A Low frequency (seismic) vibration sensor | 731-207 Low Frequency (Seismic) Vibration Sensors – Ultra-sensitive, perfect for detecting even the smallest vibrations, e.g. with active vibration compensation.

Our projects

Discover our projects & applications mechanical engineering

Fields of application and technologies

Our customers use sensor solutions such as force, displacement, pressure, or vibration sensors to precisely measure physical variables and integrate them into control systems. These measured values are used, among other things, for condition monitoring of components, control of mechanical processes, or analysis in test bench operation.

Robust sensors that can be integrated into existing machines, have high measurement dynamics, and are electrically and mechanically adaptable are particularly in demand. Applications such as LVDTs for linear movements, strain gauge-based force transducers, IEPE vibration sensors, or pressure sensors for hydraulic systems enable reliable monitoring and control even under harsh environmental conditions. In the context of digitalization, wireless sensor technology and condition monitoring systems are also gaining in importance—especially for retrofit solutions and integration into IIoT platforms.

Matching products

ALF214 Cylindrical force sensor

- Range up to 60 kN

- Output 1.2 or 1.0 mV/V

- Robust IP65 construction

ALF207 Load Washer

- Measuring range: ~10 kN to ~200kN

- For spaces with restricted height

- Various designs possible on request

AGS4200 Standard Pressure Transducer

- Measuring range: 0 - 0,5 to 0 - 1.500 bar

- Silicon-on-Sapphire sensor technology

- ± 0.25% accuracy, optional ± 0.1%

P103 Short stroke linear inductive position sensor

- Compact stainless steel housing for space-constrained environments

- Travel range from 2 mm to 50 mm

- Multiple electrical and mechanical configurations

18FLPA Series Linear Potentiometer

- Measurement range 15 mm and 100 mm

- Resistance value: 500 Ω to 20 kΩ

- Robust conductive plastic model

EPRB-1 Miniature Pressure Transducer

- Measuring range: 0 - 3,5 to 0 - 700 bar

- Combined linearity & hysteresis < 0.25%

- 100% stainless steel welded construction